Mig Versus Tig Welding

Mig Versus Tig Welding. Welding becomes more difficult and weld quality suffers as a result of the presence of oxygen and water in the atmosphere. Mig welding is more suitable if you are seeking a solution based on ease of use.

Mig is the faster method of welding, making it ideal for projects requiring higher production rates. Mig welding also needs less surface prep to get a good bond, so you’ll have fewer frustrating experiences while learning to weld with mig. Tig welding or mig welding:

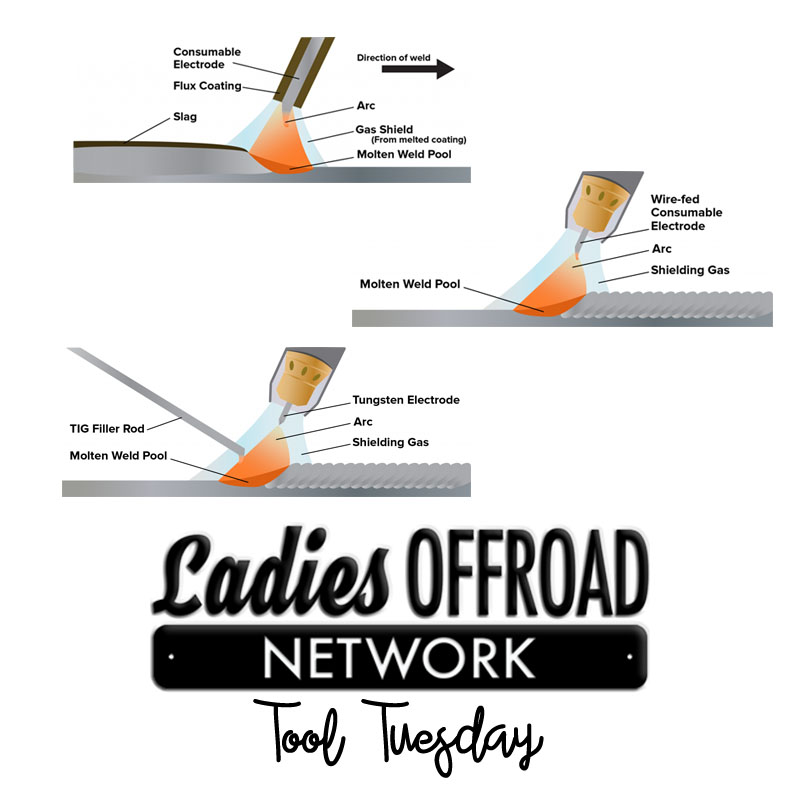

Mig (metal inert gas) welding uses a feed wire that constantly moves through the gun to create the spark, then melts to form the weld.

The inert shielding gas (argon) protects the weld pool and tungsten electrode from atmospheric grime. Tig welding tig, or tungsten inert gas, welding is a better choice for thinner and smaller materials. Mig welding is a very simple and easy learning process compared to tig welding. Mig and tig welding are both forms of arc welding.

In essence, mig welding is a faster method to complete a welding project than tig welding, provided the project is of the same size. Tig welding also works with them but in thinner gauges. Shielding gases are frequently used in gas metal arc welding (mig) and gas tungsten arc welding to protect the weld region from oxygen and water vapor (tig). It’s capable of developing fine welds, but it can direct tremendous heat into a small point, unlike mig welds’ wider heat zone.

· cost another tig vs mig welding difference is in how much they cost. Regarding investment, mig/mag equipment and its consumables are, as a rule, cheaper than tig equipment. Tungsten has an incredibly high melting point (the highest of all pure metals), so can be heated to. The main difference between mig and tig welding is that one process uses a continuous feed wire in mig welding, while tig welding uses long welding bars and the operator must feed them slowly.

Mig welding is more forgiving of mistakes than tig welding is, considering that tig welding requires precise control. Tig welding tig, or tungsten inert gas, welding is a better choice for thinner and smaller materials. Mig welding is a way faster process than tig welding, but can’t get anywhere near to tig weld when it comes to weld finish. Mig ( metal inert gas) welding is similar to stick welding in that it uses an electrode, but rather than a stiff, solid electrode it uses electrode wires, spool fed through a gun.

Mig welding is a way faster process than tig welding, but can’t get anywhere near to tig weld when it comes to weld finish. Tig welding tig, or tungsten inert gas, welding is a better choice for thinner and smaller materials. Mig welding is significantly faster than tig. The inert shielding gas (argon) protects the weld pool and tungsten electrode from atmospheric grime.

However, tig welding allows you to work with thinner materials and often results in cleaner welds. Mig welding is more suitable if you are seeking a solution based on ease of use. Tig welding or mig welding: Mig welding is faster than tig welding, which can mean shorter lead times and lower costs of production.

The final weld, however, isn’t as strong or precise as tig welds. It’s capable of developing fine welds, but it can direct tremendous heat into a small point, unlike mig welds’ wider heat zone. Mig welding also needs less surface prep to get a good bond, so you’ll have fewer frustrating experiences while learning to weld with mig. However, it is a little direct heat zone, but the consumption of heat is excessive.

· cost another tig vs mig welding difference is in how much they cost. Mig welding also needs less surface prep to get a good bond, so you’ll have fewer frustrating experiences while learning to weld with mig. Tig welding or mig welding: However, tig welding is not suitable to weld aluminum sheets of metals.

As steel is thin and hard, tig welding is perfectly suitable for this. Mig welding, on the other hand, involves feeding a wire to an electrode, which fuses your project. Mig (metal inert gas) welding uses a feed wire that constantly moves through the gun to create the spark, then melts to form the weld. Sometimes it may require light polishing or salting to remove the unwanted color.